How Airlines Are Starting To Solve NFFs?

No Fault Found (NFF) is a standard term used in aviation, and typically happens when a part removed from an aircraft, due to poor performance, is sent to an MRO repair shop for testing. The repair shop cannot replicate or find the problem. The MRO shop tests the unit and if it passes all tests, the unit is sent back to the operator as NFF.

Now, the same unit could continue having problems that cannot replicate on the bench. Many times, micro-breaks, bad soldering, vibrations, could create intermittences that are undetectable by standard equipment. The unit is removed and sent back to the MRO shop and the cycle continues. Airlines often-times have a policy to retire the unit after three NFF test results. This unit will be considered “rogue” or unserviceable.

Aircraft OEMs, also have processes to deal with rogue units.

At the MRO level, depending on the Component Maintenance Manual (CMM) for the particular part, Original Equipment Manufacturers (OEM) will provide a set of instructions on how to perform a deep test on the unit. This will entail doing a temperature test and a vibration test to capture the anomaly (“bake and shake”).

It is highly probable that after performing the deep test, with environmental stimulus (“baking and shaking”), the unit is returned to service and continues to present problems.

What are the different intermittence stages in No-

Fault Founds?

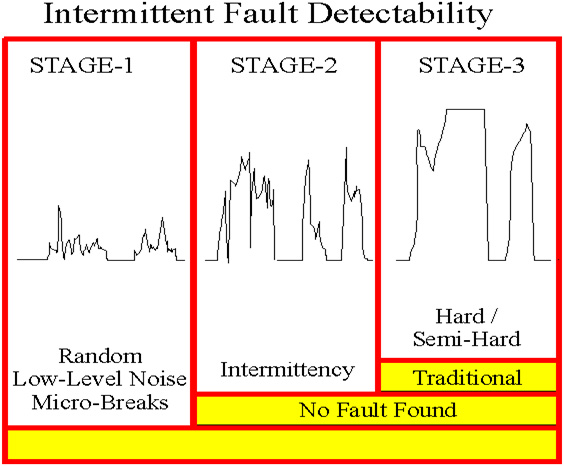

One of the possible reasons that vibration and temperature chambers still would not be able to replicate the problem is related to the sensitivity of the equipment. There are three stages in which intermittences occur.

Stage 1 Stage 2 Stage 2 intermittences graph for NFFs

- Stage-3 hard or semi-hard failures can be captured by most test equipment on the bench or the line.

- Stage-2 faults that manifest intermittently in operation, but pass the deep test, and labeled NFF.

- Stage-1 random low-level nanosecond micro-breaks or noise, likely not operationally evident.

Equipment capturing Stage-3 hard or semi-hard fault is not built and not capable of capturing Stage-1 or Stage-2 intermittent faults where these micro-breaks are detected.

Micro-breaks could occur as follows:

• Cracked solder joint.

• Broken wire.

• Loose crimp connection.

• Loose or corroded wire wrap.

• Corroded connector contact.

• Sprung connector receptacle.

• Deteriorated wire insulation.

• Hairline crack in printed circuit trace.

• Unsoldered connection.

Micro-breaks due to corrosion. Source: Universal Synaptics |

Micro-break due to bad contact. Source: Universal Synaptics |

Recent Comments