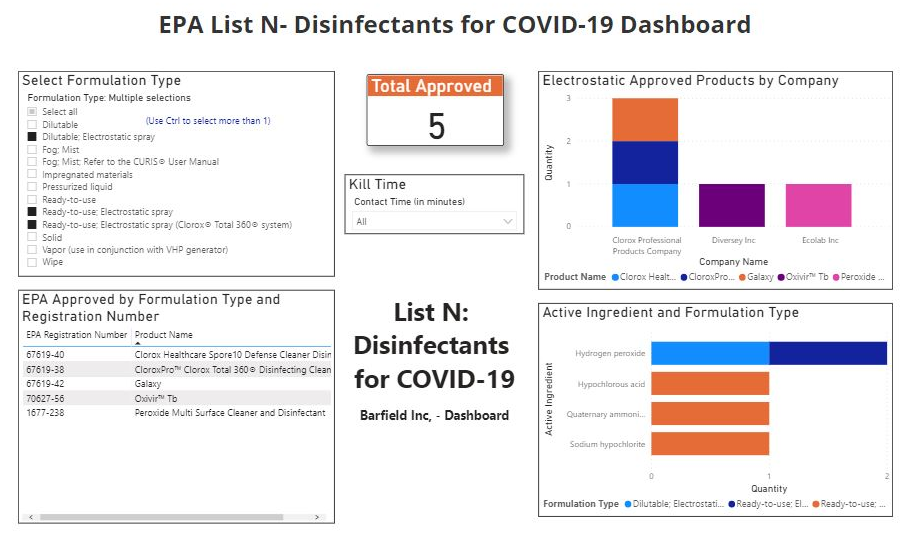

Electrostatic EPA Approved Disinfectants Dashboard

The Environmental Protection Agency ( EPA) recently announced the approval of the use of disinfectant electrostatic equipment. With the emergence of electrostatic equipment manufacturers of disinfectant products will have to display on their labels, the compatibility of applying their product using an electrostatic sprayer.

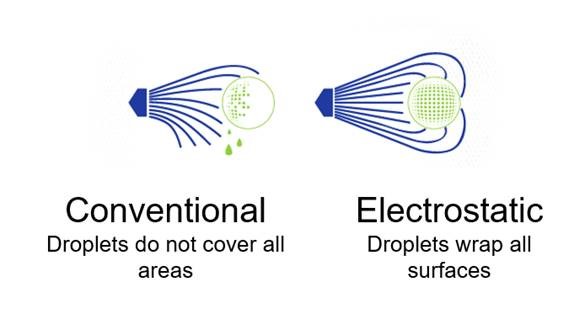

The popularity of electrostatic sprayers is their ability to charge disinfectant particles positively, once sprayed, they adhere to negative surfaces, wrapping them around. Barfield, uses the Cube from On Target Spray Systems for its disinfecting needs.

To help navigate the information from the EPA our team of data visualization extracted the information from their website creating the dashboard below. It is designed to help our aviation partners better understand the type of product, kill time, and applications.

To follow what OEMs approve regarding aircraft interior disinfection, please refer to their manuals or service information letters. For corporate aircraft, the National Business Aviation Association has compiled good information. To learn more, click on the following link Coronavirus Disease 2019 ( COVID-19)

Below is a step by step guide on how to use the dashboard:

The following menus are available:

- Select Formulation Type: There are different options available. Here Dilutable: Electrostatic spray, Ready-to-use: Electrostatic spray and Ready-to-use: Electrostatic spray ( Clorox Total 360 system) has been selected

- Kill Time: It filters the available kill time by product selected

Explanation of tables and charts:

- EPA approved number by product name (bottom left).

- List of companies with an electrostatic approved product (top right).

- Active ingredient by Formulation Type (bottom right).

- Total number of approved products depending on the selection (middle).

Try interacting with the dashboard below:

EPA List N- Disinfectants for COVID-19 Dashboard

This information was last updated on 10/08/2020.

As new products are approved for electrostatic spraying use, our team will be updating this dashboard as often as possible.

You might also be interested in the following related articles:

Do you want to learn more about it?

Click here to check the videos and technical specifications

Recent Comments