Ground Support Test Equipment

No Fault Found (NFF) is a standard term used in aviation, and typically happens when a part removed from an aircraft, due to poor performance, is sent to an MRO repair shop for testing. The repair shop cannot replicate or find the problem. The MRO shop tests the unit and if it passes all tests, the unit is sent back to the operator as NFF.

Now, the same unit could continue having problems that cannot replicate on the bench. Many times, micro-breaks, bad soldering, vibrations, could create intermittences that are undetectable by standard equipment. The unit is removed and sent back to the MRO shop and the cycle continues. Airlines often-times have a policy to retire the unit after three NFF test results. This unit will be considered “rogue” or unserviceable.

Aircraft OEMs, also have processes to deal with rogue units.

At the MRO level, depending on the Component Maintenance Manual (CMM) for the particular part, Original Equipment Manufacturers (OEM) will provide a set of instructions on how to perform a deep test on the unit. This will entail doing a temperature test and a vibration test to capture the anomaly (“bake and shake”).

It is highly probable that after performing the deep test, with environmental stimulus (“baking and shaking”), the unit is returned to service and continues to present problems.

What are the different intermittence stages in No-

Fault Founds?

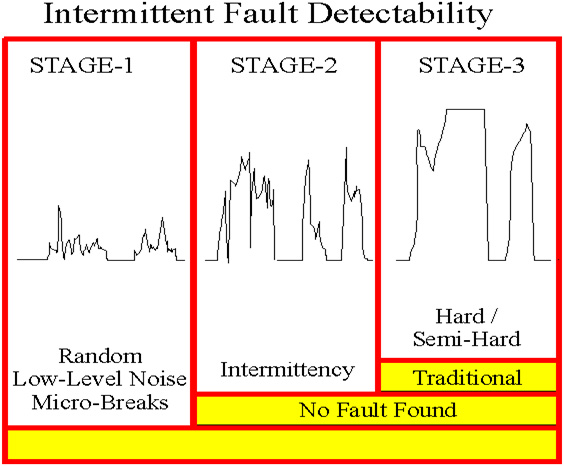

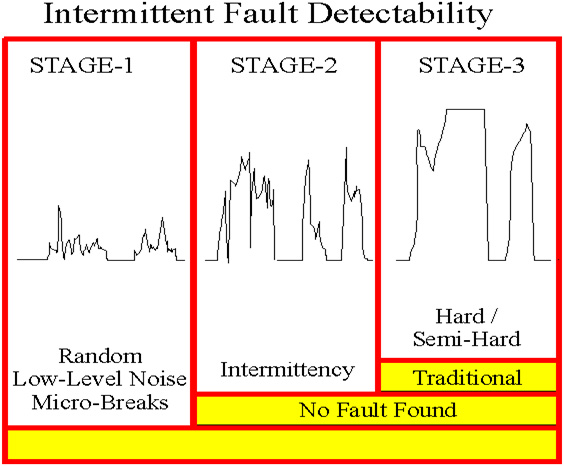

One of the possible reasons that vibration and temperature chambers still would not be able to replicate the problem is related to the sensitivity of the equipment. There are three stages in which intermittences occur.

Stage 1 Stage 2 Stage 2 intermittences graph for NFFs

- Stage-3 hard or semi-hard failures can be captured by most test equipment on the bench or the line.

- Stage-2 faults that manifest intermittently in operation, but pass the deep test, and labeled NFF.

- Stage-1 random low-level nanosecond micro-breaks or noise, likely not operationally evident.

Equipment capturing Stage-3 hard or semi-hard fault is not built and not capable of capturing Stage-1 or Stage-2 intermittent faults where these micro-breaks are detected.

Micro-breaks could occur as follows:

• Cracked solder joint.

• Broken wire.

• Loose crimp connection.

• Loose or corroded wire wrap.

• Corroded connector contact.

• Sprung connector receptacle.

• Deteriorated wire insulation.

• Hairline crack in printed circuit trace.

• Unsoldered connection.

Micro-breaks due to corrosion. Source: Universal Synaptics |

Micro-break due to bad contact. Source: Universal Synaptics |

(more…)

Ground Support Test Equipment

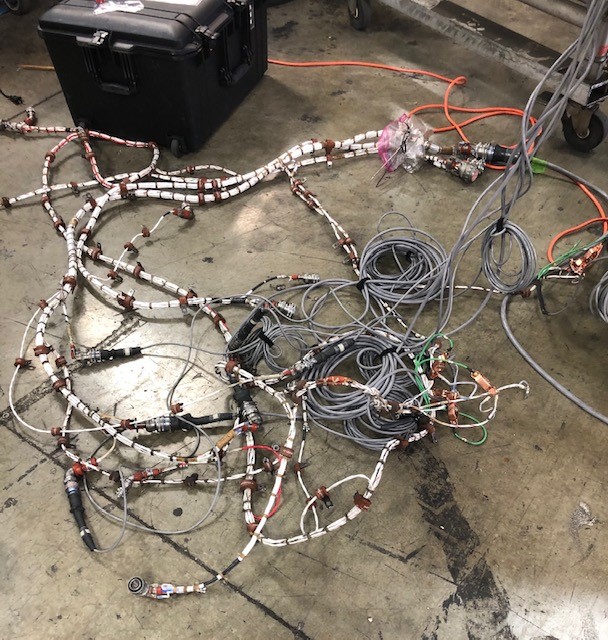

Intermittence fault is a known problem in aircraft due to a large number of electrical wire and complex systems that make an aircraft. Newer aircraft have more computer-based system which has even more wiring than legacy aircraft.

Why aircraft intermittences are so difficult to detect?

Finding a problem in a bundle of wire-harness is a complex challenge. Sporadic intermittences that appear in mid-air are detected and reported by pilots. Once the aircraft is back on the ground these intermittences are difficult, if not impossible for technicians to replicate. Aircraft vibration can not easily be replicated, and many times the intermittences happen in fractions of milliseconds.

Therefore, problems observed in mid-air can not easily be replicated on the ground. Technicians rely on ohmmeters to run conductivity testing, selecting line by line, looking for the problem. The tool of choice, a multimeter, is set up to find transients with millisecond accuracy. There are two challenges with this approach:

- Harnesses are interconnected systems of multiple wires, and a multimeter is only capable of testing one wire at a time.

- It is possible that the transients occur in less than a millisecond, undetectable by the multimeter.

Problems observed in mid-air can not easily be replicated on the ground.

Hence, the multimeter works to detect open circuits, which is considered hard or semy hard intermittences. But not accurate enough to detect random sporadic intermittences at low-level noise or micro-breaks.

New Technology

New technology has emerged. It takes into consideration all electrical lines by testing each line simultaneously with a nanosecond accuracy in a closed-loop environment. This technology uses a hardware version of a neural network, in which signals are sent to each node combining all feedback back to the analyzer. Then, the system could be checked as a whole, and not each line separately, creating the necessary environment to detect any fault.

New technology has emerged. It takes into consideration all electrical lines by testing each line simultaneously with a nanosecond accuracy in a closed-loop environment.

The United States Department of Defense is one of the early adopters of this technology that tests LRU, by extending the mission capability of their fleet and reducing operating costs.

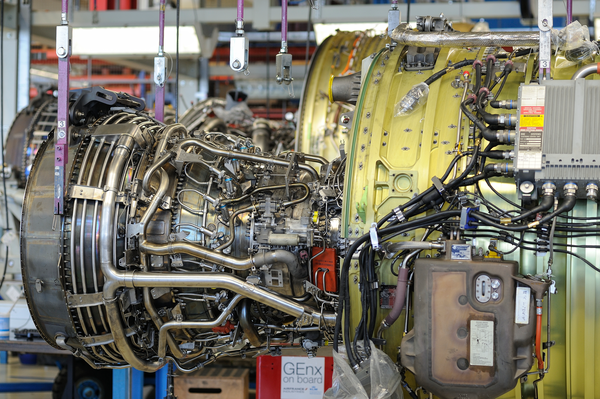

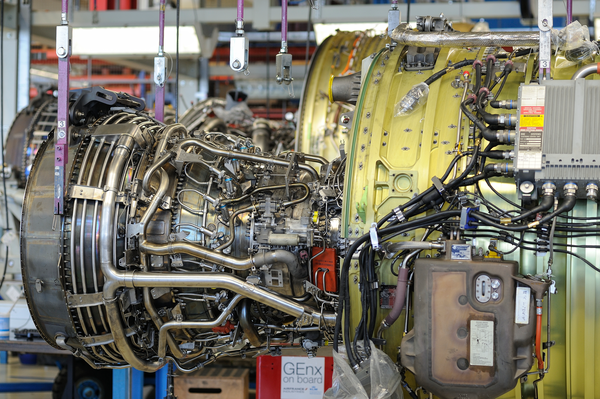

GE-90 Wire Harness Case Study

We have identified by Boeing 777 operators that the GE-90 115B engine typically shows intermittency problems in the wire harness. Our engineer group along with the team at Universal Synaptics developed an interface, to connect the bundle of wires into the IFD (portable).

The complexity of this task can only be solved by sending simultaneous pulses at a nanosecond speed through all cables simultaneously. The IFD (portable) connects in series with the wire harness and detects any possible anomaly.

This report shows the results of the test. GE 90 complex cables IFD Universal Synaptics

Lockheed Martin with F-16

Lockheed Martin currently uses the versions of the IFD on their different platforms. Check video below:

Several case studies have come to light recently and a selected group can be downloaded here:

Selected Aircraft Case Studies:

- F-16 Nose Landing Gear Harness.

- Boeing 777 GE90 Engine Harness

- Total Air Temperature Probes .

- Pratt & Whitney V2500 Engine Harness

- AH-64 Apache EWIS Testing

- Elevator and Aileron Computer (ELAC)

Barfield Inc., in partnership with Universal Synaptics, is bringing this technology to operators of commercial and business aircraft.

If you still have more questions or want to learn more about this technology, please fill out the form below.

Contact us here, for more information.

Recent Comments