How to set the limits of the DPS1000 and 1811NG?

Using incorrect limits can cause damage to sensitive components and aircraft systems.

For that reason, it is very important to ALWAYS verify and ensure the limits selected are appropriate for the aircraft and/or the instruments that are going to be tested.

The DPS1000/1811NG Test Sets come with two (2) pre-defined sets of operating limits – the default limits profile and the max limits profile. These limits are available for each of the of the three (3) operating modes – Aeronautical, Pressure units and EPR.

Both DPS1000 and 1811NG Test Sets include a setting that allows creating and saving custom limits. With this feature, the customer can easily access and use the custom limits again in the future.

The values for both limits profiles are stored in an R/O, “read only”, file. The Test Set will first power up and initialize with the default limits profile. As a result, if the customer changes the limits to the max or custom limits profile, the Test Set will power up using the last profile selected.

The Test Set limits must be configured with the appropriate values to protect the aircraft system or instrument(s) about to be tested.

“…it is very important to ALWAYS verify and ensure the limits selected are appropriate for the aircraft and/or the instruments that are going to be tested.“

How to set up the limits

NOTE: Before creating new limits refer to the appropriate AMM (Aircraft Maintenance Manual) or CMM (Component Maintenance Manual) for the actual minimum and maximum values to be applied.

A. If the limits don’t exist:

Go to Setup 2 and create the limit file following these steps:

- From Main Menu display, press “Page 2” button.

- Screen is displayed with four options (Setup 1, Setup 2, Setup 3 and Change User Pin#). Select Setup 2.

- From keypad screen, input user PIN (manufacturing default PIN: 123456– unless already changed by the user).

- Select Limits Create/Edit/Delete.

- Select Create Custom Limits – enter the parameter values for ALT, ROC, CAS, RtCAS, MACH, and ALR (Auto Leak Recovery). Note: You can select each parameter by touching the parameter or cycle through each parameter using the “Enter” key.

Note: It’s recommended to Save the Limits with the aircraft name.

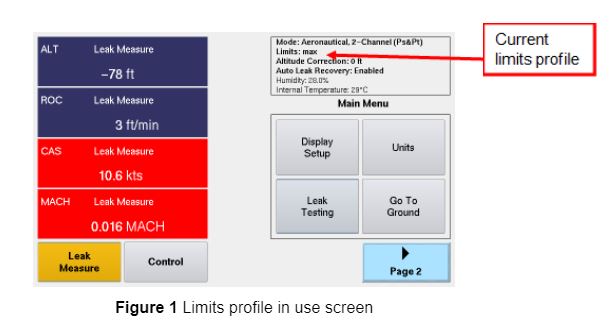

The limits profile currently in use is displayed on the right upper quadrant of the screen (Figure 1).

B. Selecting limits:

If the operating limits exist because they were already created go to Setup 1 and select the limit file following these steps:

- From Main Menu, press “Page 2” button.

- Screen is displayed with four options (Setup 1, Setup 2, Setup 3 and Change User Pin#). Select Setup 1.

- Touch “Limits View/Select” key.

- Touch “Select Limits”

- Select applicable limit from the list displayed.

- Click OK.

NOTE: The tables showing the default and max limits profile values included in the DPS1000/1811NG Test Sets can be found in the corresponding user instruction manuals under “Appendix B: Operating Limits”.

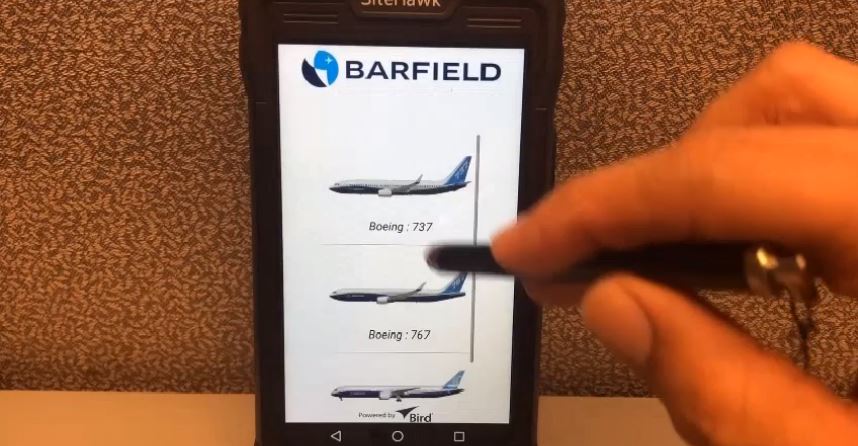

Viewers of this article also were interested on How to Connect the DPS1000 and 1811NG to a Tablet

Have you Registered your Barfield Product?

Registering your product validates your warranty and provides yout technical updates

Recent Comments