AFI KLM E&M American Subsidiary comes into an agreement with On Target Spray System to distribute its state-of-the-art Electrostatic Cart to combat the spread of COVID-19.

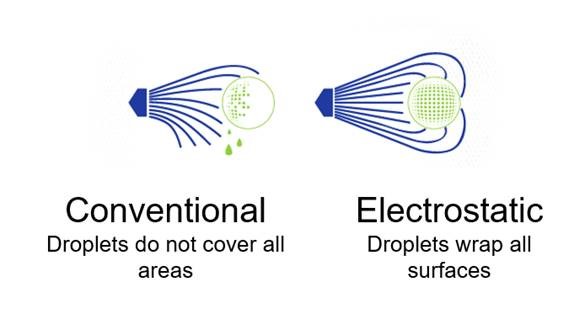

Paris, Amstelveen, Miami, July 2020 – Barfield Inc., a subsidiary of Air France KLM Engineering & Maintenance (AFI KLM E&M) in the Americas, will now distribute the Electrostatic Cart from On Target Spray System, to help prevent the spread of COVID-19. The Electrostatic Cart 3D wraparound technology is three times faster than fogging and provide uniform coverage of all surfaces.

On Target Spray System’s Electrostatic Cart offers a readily solution in a time when disinfecting has become the norm and organizations need the most effective tool to help keep people healthy and safe. “We are very excited to partner with On Target Spray System as part of our strategy to create solutions for our customers. The COVID-19 pandemic has changed our way of life and the Electrostatic Sprayer is here to ensure peace of mind wherever we go,” says Herve Page, Chief Executive Officer of Barfield.

The Electrostatic Cart comes with roller cart and an On Target wrap around patented technology designed to be cost effective and save customers time. The Cart is built in the United States for heavy duty work and has robust air compressors designed to disinfect any aircraft cabin interior as well as exterior.

“We value our partnership with Barfield as their support will help the Electrostatic Spray reach a wider audience outside our traditional industry. Barfield’s 75 years reputation and continued excellence in customer service allows to trust them with the vision of this product,” says Willie Hartman, President of On Target.

About Barfield Inc.

Barfield consists of 500 employees across its facilities in Miami, Phoenix, Louisville and Atlanta. With its leading facilities, Barfield can satisfy the needs of customers operating commercial or regional fleets in North, Central and South America. From MRO Services to Distribution and Ground Support Test Equipment (GSTE), Barfield provides complete tailor-made support programs for A320 family, 737, Bombardier, Dash 8, ATR 42 & 72 and Embraer 170 & 190 aircraft to operators in need of inventory and logistics solutions, repair management programs, engineering and fleet support, and component reliability management. Barfield is part of the AFI KLM E&M network, a major MRO provider. To find out more about electrostatic sprayering check this site: blog.barfieldinc.com/fightcovid19

www.barfieldinc.com

About On Target

On Target was founded in 1995 and is headquartered in Mt. Angel, Oregon. The company has focused solely on electrostatic spray technology for agriculture. On Target offers 40 sprayer models for 14 crop

segments in 10 countries. On Target made a quick pivot to offer new models to battle COVID and help keep people safe. www.ontargetspray.com

About AFI KLM E&M

Air France Industries KLM Engineering & Maintenance is a major multi-product MRO (Maintenance, Repair, Overhaul) provider. With a workforce of over 14,000, AFI KLM E&M offers comprehensive technical support for airlines, ranging from engineering and line maintenance to engine overhaul, aero structure and fan thrust reverser support, as well as the management, repair and supply of aircraft components, structured around a powerful logistics network. AFI KLM E&M supports almost 2,000 aircraft operated by 200 major international and domestic airlines. www.afiklmem.com or mobile.afiklmem.com

Recent Comments