Why Are Turbine Temperature Testers Critical In Aviation?

Turbine temperature indicating systems are critical for proper aircraft maintenance. This article helps explain the main difference between the Barfield TT1000A and TT1200A test sets.

What do they do?

The three primary functions of a Barfield turbine temperature test set are:

- Measure the Resistance of the aircraft thermocouple loop system.

- Measure the insulation between either of the thermocouple conductors and the airframe chassis.

- Test the cockpit indicator using a thermocouple simulator.

Additionally, the Barfield Turbine Temperature Test Sets also have the ability to:

- Simulate the in-line resistance required on many older indicating systems.

- Provide cold junction compensation (for ambient) at the point of connection.

- Measure the engine temperature directly, as it may be used as a master indicator.

Why do aircraft operators need these tools?

Their main purpose is to be able to Test, Troubleshoot and Certify the accuracy of the aircraft’s Turbine Temperature Indicating System.

This is accomplished by using the aircraft’s maintenance manual (AMM) to determine the specific tests required with their allowable tolerances and the Barfield supplied instruction manual which details the test set configuration and hook-up information for the test procedures.

How does the tool interact with the engine and the instruments of the aircraft?

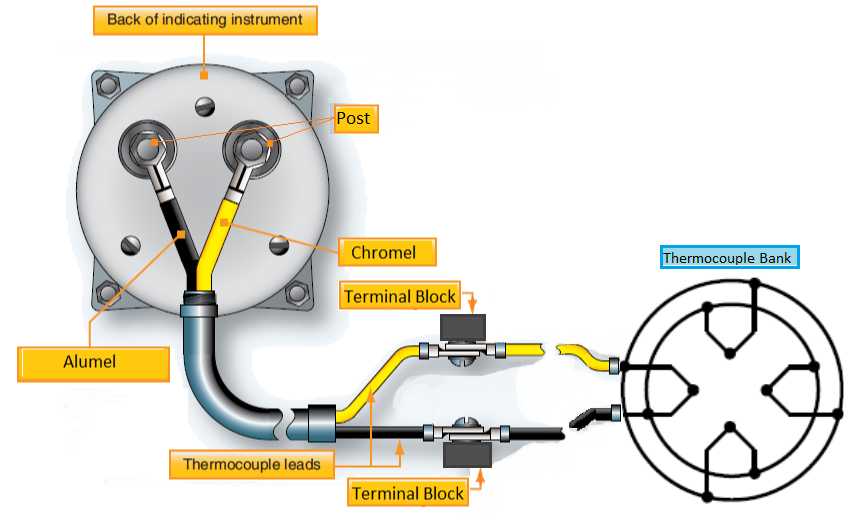

The Barfield Turbine Temperature Test Sets are used to test the aircraft wiring, thermocouple sensors, and the cockpit indicator. Typically, this is done using a divide and conquer scheme where the aircraft wiring and thermocouple sensors are isolated from the cockpit indicator or indicating system and tested separately.

The equipment is then used to test and troubleshoot in order to find and repair or replace any components not meeting the required specifications for either resistance or insulation. The indicator is then tested apart from the aircraft wiring and thermocouple sensors using the tester’s thermocouple simulator to perform an indicator run-out to confirm accuracy and linearity.

What aircraft uses these tools?

The Barfield Turbine Temperature Test Sets may be used on any and all types of aircraft that have some form of a turbine engine(s) whether turbofan, turboprop, or turboshaft, and which use chromel-alumel (K type) thermocouples to sense the engine temperature.

Why are they important for aviation owners?

They are important to ensure that their aircraft engine temperature indicating systems are reading accurately.

Various issues with the aircraft indicating system will cause the cockpit indication to read lower than it should and so there is an increased risk of over-temping the engine if the system is not certified.

Thus, technicians rely on their test equipment to return aircraft back to service.

What are their differences?

| FEATURE | TT1200A | TT1000A |

| Display Temperature | °C, °F & Millivoltage | °C only |

| Thermocouple range | Up to 1372° | Up to 1000°C |

| Temperature display resolution | 0.1°C | 1°C |

| Backlit 16 Character | Yes | No |

| Does it require separate 45V battery (or Converter with 9V)? | No | Yes |

| Access to batteries without disassembly | Yes | No |

| Is the housing ruggedized and highly visible? | Yes | No |

| Number of resistance and insulation ranges | 4, 4 | 2, 1 |

| Resistance measurements to | 0.001Ω | 0.01Ω |

| Insulation measurements to | 200MΩ | 2MΩ |

| Smart Calibration alert reminder Technology | Yes | No |

| Timed measurement with Display Hold feature for Resistance and Insulation functions | Yes | No |

| Embedded password security to prevent unauthorized access to certain options of the menu | Yes | No |

| Standard and custom test leads are connected using same panel mounted cannon plug | Yes | No |

In summary:

Both the TT1200A and TT1000 Test Sets provide:

- 4-Wire Resistance Measurements to perform the required system resistance measurements

- 45V Insulation Test to test for insulation breakdown of the wiring, sensors, and interconnects

- A Thermocouple Simulator to perform Indicator run outs

- Temperature measurement and may be used as a master indicator

- Resistance simulation to provide the required in-line resistance for non-powered analog indicators

- Cold Junction Compensation at the clips for much faster temperature stabilization

Use the TT1200A if the aircraft engine temperature indicating system requires greater than 1000°C or has indications in °F or if the temperatures are presented with 0.1-degree resolution.

Also, use the TT1200A if the system or any individual components have resistance values specified to resolutions of 0.001Ω or have any insulation test requirements of greater than 2MΩ specified.

Otherwise, the TT1000A could meet the turbine temperature requirements.

Where to find the manuals?

To learn more about the proper usage and interfacing of the test sets, please refer to the appropriate Instruction Manuals, available on our website barfieldinc.com.

Recent Comments